In a fascinating intersection of biotechnology and music, scientists have recently unveiled a groundbreaking innovation: spider silk violins enhanced through genetically edited silkworm silk. This remarkable fusion of nature and engineering promises to revolutionize the acoustic qualities of string instruments, offering musicians a new realm of tonal possibilities. The implications extend beyond mere sound quality, touching upon sustainability, material science, and the future of instrument craftsmanship.

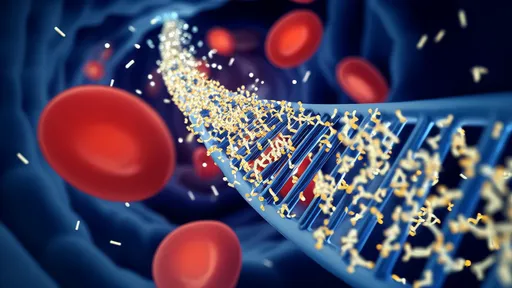

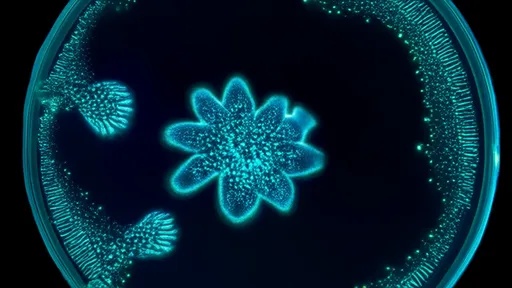

The concept of using spider silk for its exceptional strength and elasticity is not new. For centuries, spiders have spun silk that outperforms many synthetic materials in tensile strength and flexibility. However, harvesting spider silk on an industrial scale has proven impractical due to spiders' territorial and cannibalistic nature. Enter genetic engineering: researchers have successfully modified silkworms to produce silk that incorporates key proteins found in spider silk, resulting in a hybrid material that retains the best properties of both.

When applied to violin strings, this bioengineered silk demonstrates extraordinary acoustic properties. Early tests reveal a richer, more resonant tone compared to traditional gut or steel strings. The material's unique molecular structure allows for superior vibration transmission, producing harmonics that were previously unattainable. Professional violinists who have tested prototype strings describe the sound as "warmer" with "unprecedented clarity in the upper registers."

Beyond sound quality, these spider-silk violin strings offer practical advantages. They are more durable than conventional strings, resisting wear and environmental changes that typically affect tone over time. This durability could significantly reduce maintenance costs for professional musicians. Additionally, the production process is more sustainable than traditional string manufacturing, which often relies on non-renewable resources.

The development process wasn't without challenges. Scientists spent years perfecting the genetic modifications to ensure the silkworms produced silk with consistent quality. The spinning and weaving techniques had to be adapted to handle the unique properties of the hybrid material. Instrument makers then faced the task of incorporating these new strings into existing violin designs, requiring adjustments to bridge height and sound post placement to fully realize the strings' potential.

This innovation opens exciting possibilities for the future of musical instruments. Researchers speculate that similar bioengineering techniques could be applied to other instrument components, potentially creating entire instruments with enhanced acoustic properties. The success of spider-silk violin strings may inspire a new wave of biomimicry in musical instrument design, blending ancient craftsmanship with cutting-edge science.

As this technology develops, ethical questions emerge regarding genetic modification and its applications. However, the musical community largely views this development as a positive step forward, offering new creative possibilities while addressing sustainability concerns. With commercial production expected to begin within the next two years, spider-silk violin strings may soon become a standard choice for musicians seeking superior sound quality and performance.

The implications extend beyond classical music. The same technology could enhance strings for guitars, harps, and other instruments, potentially transforming entire musical genres. As we stand at the crossroads of biology and music technology, the spider-silk violin represents more than just an instrument upgrade—it symbolizes humanity's ability to harness nature's genius to enrich our cultural expressions.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025