The logistics industry stands on the brink of a transformative leap with the advent of vacuum tube cargo systems, a futuristic concept that merges magnetic levitation (maglev) technology with hyperloop-inspired vacuum pipelines. This innovation promises to redefine freight transportation by enabling ultra-fast, energy-efficient, and weather-resistant delivery of goods. Dubbed the "maglev capsule revolution," this system could soon render traditional trucking and rail freight obsolete for high-priority shipments.

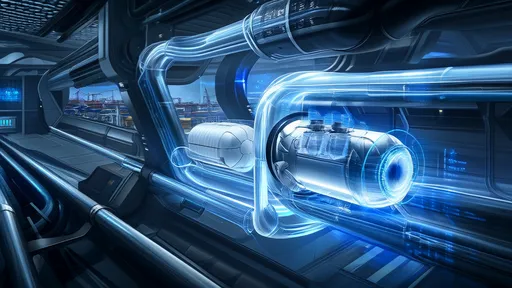

At the heart of this breakthrough is the elimination of air resistance and friction—two major bottlenecks in conventional transport. By deploying hermetically sealed tubes maintained at near-vacuum conditions, maglev capsules can theoretically achieve speeds exceeding 1,000 km/h while consuming minimal energy. Early prototypes have demonstrated the viability of accelerating 500-kg payloads from standstill to 600 km/h in under two minutes, a feat impossible with diesel-powered vehicles. The capsules themselves are marvels of engineering: aerodynamically sculpted aluminum alloy shells with superconducting magnets that hover 10 cm above guideways, eliminating wear-and-tear.

The implications for global supply chains are staggering. Perishable goods like pharmaceuticals and fresh produce could traverse continents in hours rather than days, virtually eliminating spoilage losses. Automotive manufacturers are already experimenting with just-in-time part deliveries between factories using test loops, reducing inventory costs by 40% in pilot programs. Perhaps most compelling is the environmental argument—studies suggest vacuum tube networks could slash freight-related carbon emissions by 90% compared to air cargo when powered by renewable energy.

However, the path to mainstream adoption isn't without obstacles. The upfront infrastructure costs are astronomical, with estimates of $50 million per kilometer for urban installations requiring deep-bore tunneling. Regulatory hurdles abound, particularly regarding right-of-way permissions for cross-border tubes. Skeptics also question the system's vulnerability to seismic activity, though engineers counter with flexible joint designs that can accommodate 30 cm of lateral movement during earthquakes.

China has emerged as the unexpected frontrunner in this space, having secretly constructed a 3.2 km test track in Chengdu that achieved 620 km/h with full payloads in 2023. Meanwhile, European consortiums are focusing on standardized capsule interfaces that could integrate with existing warehouse robotics. The United States lags behind, though Amazon's recent patent filings for "pressure-regulated cargo pods" suggest impending private sector involvement.

What makes this technology truly revolutionary isn't just the speed—it's the potential to create a parallel logistics universe. Imagine dedicated vacuum lines for hazardous materials eliminating highway risks, or underground networks supplying megacities without adding surface congestion. The first commercial routes for high-value electronics transport are projected to launch by 2028, with proponents arguing the system will pay for itself within seven years through labor and fuel savings.

As with any paradigm shift, workforce displacement concerns loom large. The International Transport Workers' Federation warns that 12 million trucking jobs could become redundant, necessitating massive retraining initiatives. Conversely, new specialties like vacuum tube maintenance and capsule traffic control are expected to create 3 million technical positions globally by 2035.

The coming decade will determine whether vacuum tube freight transitions from spectacular experiment to transportation mainstay. While the challenges are formidable, the combined pressures of climate change, e-commerce growth, and supply chain fragility make a compelling case for this audacious solution. One thing is certain: the centuries-old model of putting wheels under cargo is about to face its most serious challenger yet.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025