As the world shifts toward sustainable infrastructure, engineers are reimagining the very pavement beneath our wheels. Piezoelectric roads—a concept once confined to laboratories—are now emerging as a viable solution to harvest energy from the everyday movement of vehicles. These "smart" pavements embed specialized materials that convert mechanical stress from passing cars into usable electricity, turning traffic into a power source.

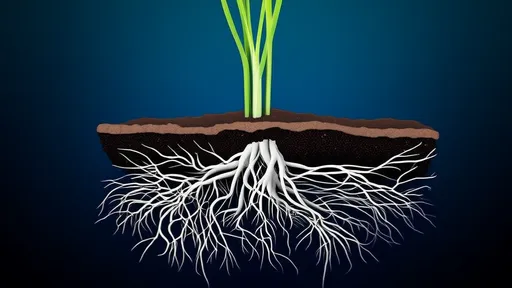

The technology hinges on the piezoelectric effect, where certain crystals or ceramics generate voltage when subjected to pressure. When integrated beneath asphalt layers, these materials capture vibrations from tires, transforming kinetic energy that would otherwise dissipate as heat. Early pilot projects in cities like Tel Aviv and Los Angeles suggest that a single kilometer of such roadway could theoretically power dozens of streetlights or charge electric vehicles wirelessly at stoplights.

From Lab to Lane: The Engineering Breakthroughs

What makes modern piezoelectric roads feasible is a cocktail of material science innovations. Traditional piezoelectric ceramics like PZT (lead zirconate titanate) were brittle and costly, but newer composites infused with polymers or graphene offer durability against truck weights while maintaining efficiency. Researchers at the University of California have even developed flexible piezoelectric "ribbons" that can be laid during routine road repairs, slashing installation costs by 60% compared to full-depth replacements.

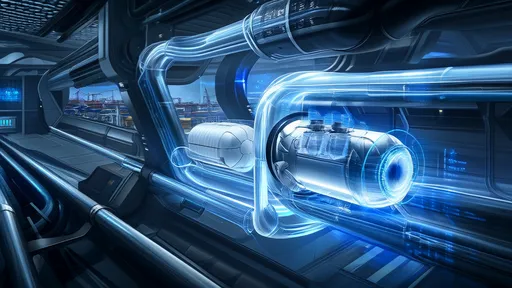

Another leap forward is adaptive circuitry. Unlike early prototypes that wasted energy through impedance mismatches, current systems use AI-driven power management chips. These devices dynamically adjust electrical resistance based on real-time traffic flow—prioritizing energy capture during rush hour while minimizing losses during lulls. Trials in Germany’s Autobahn segments show this boosts net output by 35%.

The Hidden Infrastructure Revolution

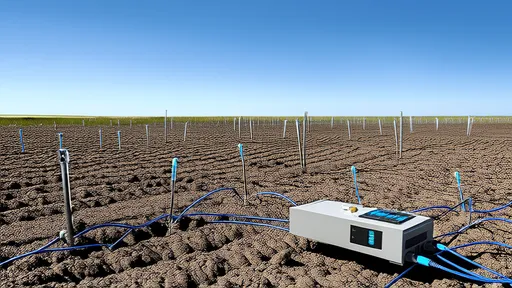

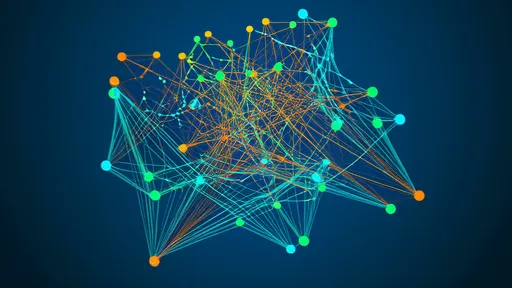

Beyond energy generation, piezoelectric roads double as data-gathering networks. Each vibration pulse carries information about vehicle speed, weight distribution, and even tire health. When networked with IoT sensors, this enables predictive maintenance—alerting crews to pothole risks before they form. In Stockholm, such systems have reduced road repairs by 22% annually.

Critics initially questioned the economic viability, citing the 2006 Italian experiment where maintenance costs overshadowed benefits. However, the calculus has changed. With modular designs and 20-year lifespans in recent models, lifecycle analyses now project ROI within 7–10 years—especially when paired with toll-road subsidies or carbon credits. The U.S. Department of Energy’s 2023 report estimates nationwide implementation could offset 3% of transportation-sector emissions.

Drivers as Power Producers: The Behavioral Shift

Interestingly, the psychological impact on motorists is becoming a research focus. A 2023 Cambridge study found that drivers on piezoelectric test routes unconsciously adopted smoother acceleration patterns when shown real-time energy generation displays—reducing wear-and-tear while increasing output. This "eco-feedback" effect hints at roads that passively educate users toward sustainable habits.

As freight companies like Maersk begin investing in piezoelectric truck lanes for their logistics hubs, the narrative shifts from mere energy harvesting to symbiotic transportation ecosystems. The road is no longer just a surface to traverse; it’s an active participant in the energy transition—one tire vibration at a time.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025